Ensuring the areas that we work in are safe is one of the paramount considerations when risk assessing when entering a confined space or a process operation.

Mines and tunnels will operate a forced ventilation network comprising of fans and ducting. The fresh air will be forced to working areas within a mine or tunnel, such as the production face, or the TBM (Tunnel Boring Machine).

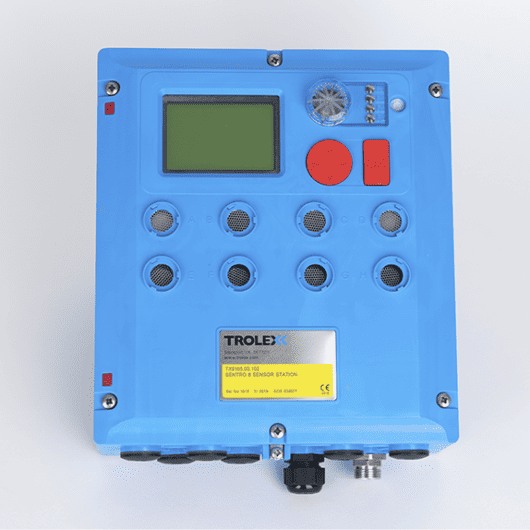

Monitoring of toxic and flammable gases in a tunnel construction project is mandated in the UK under BS6164, and the majority of tunnel construction projects will install fixed environmental monitoring stations at intervals of between 300m and 500m.

MTI Tech Ltd engineers have over 15 years in deploying & maintaining environmental monitoring systems in mines and tunnels globally.