Breweries - Fixed Gas Detection

Breweries, like wineries or other ethical beverage-making, fall under strict guidelines for safety and quality. Despite the size of brewery, from large mega-facilities to craft and boutique breweries, gas hazards are present. The gas hazards in breweries exist in both centuries old techniques and with modernized processes. Protecting workers in breweries means monitoring for toxic gas exposures and asphyxiation risks. See the reverse for brewery gas detection solutions for facilities of all sizes.

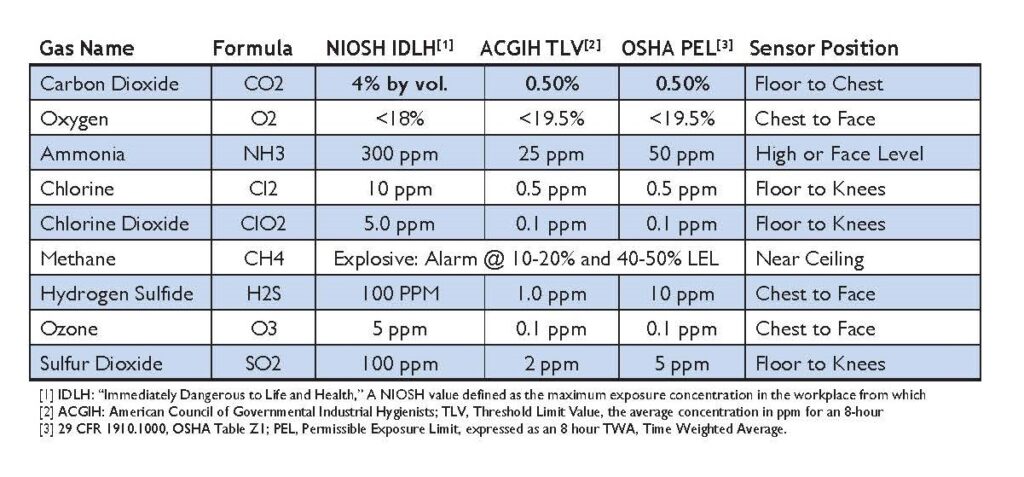

Carbon dioxide (CO2) is the fizz and forms the head on beer. High concentrations of CO2 are toxic and can cause severe breathing difficulty. Above 1,000 PPM (0.1%) CO2 causes drowsiness. A note of caution, CO2 is heavier than air and cellar or low lying and enclosed areas may be very hazardous. Monitor CO2 from floor to chest level.

Breweries of all sizes have requirements for gas monitoring. The gases and specific processes listed above are the more common applications however, with each facility unique needs may exist. Gaining the assistance of an experienced application expert is recommended for a review of existing monitoring systems and maintenance processes.

The Solution for Gas Monitoring in Breweries

MTI Tech work exclusively with Sensidyne – Sensidyne provides a comprehensive and highly reliable solution for monitoring CO2, Toxic gases, Oxygen deficiency, and alcohol in facilities brewing and distributing beer, wine, and spirits. Our team of application experts welcome the opportunity to assist customers design and specify a system for the protection of their facility.